GENERAL SPECIFICATIONS

| Material | UPVC, PP, CPVC, PVDF, SUS304, SUS316; |

| Working Pressure | 0~1.0MPa or

0~1.6MPa |

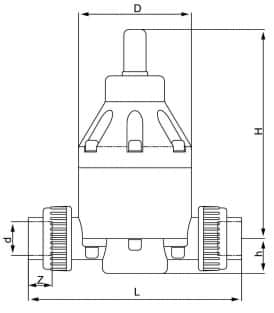

| Inlet/Outlet Size | DN15, DN20, DN25, DN32, DN40, DN50, DN65 |

| Connection Method | Glue Union, Weld Union, Threaded, Flange, Hose Compression Fitting |

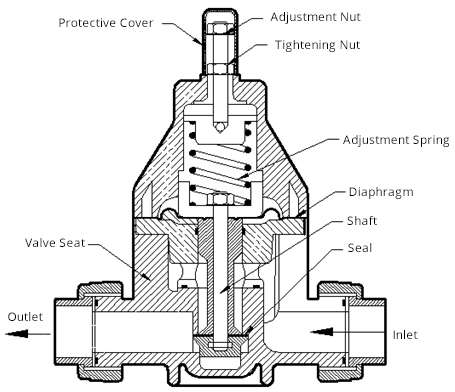

| Diaphragm | PTFE + Rubber |

FEATURES

- Ensure the system pressure is stable and consistent, prevents over pressurized your system.

- Protect your pumps and ensure system stability.

- Reduce flow fluctuation and protect your system from vibrations caused by the flow fluctuation.

- Diaphragm is made of a combination of PTFE and Rubber. Designed to handle corrosive liquid and ensure top performance sealing without leakage.