Dosing pumps are a commonly used product across a range of industries. These can by anyone from Water Treatment, Electroplating, Mining to Pulp and Paper industries. Even the medical Pharmaceutical industry uses dosing pumps for a variety of functions.

The main purpose of using a dosing pump is to cause a flow and chemical reaction in a body of fluids even if it is a simple one such as adjusting the PH level or the chlorine level as is commonly done for swimming pool water.

While in many cases an acid is injected into the water for a particular chemical reaction, flocculants are also used to make solids settle down to the bottom. Flocculating agents can also change the composition of the water and make it safe to use.

Dosing is however not only for changing the properties of water, but it does also help in manufacturing various products.

Dosing pumps are helpful in metering of fluids, corrosion inhibitors, biocides, high pressure and high-temperature fluids such as boiler feed can also be treated with dosing pumps, although changes in components used manufacturing dosing pumps are often required such as using polypropylene, aluminum, stainless steel instead of just poor quality plastic dosing pipes.

First Consider These Before Setting Up Dosing Pumps

Whenever chemicals or high pressure / temperature substances are handled, we must first take precautions for safety because you may be working with highly dangerous chemicals for dosing process. If wrongfully handled, operator error, pumping inaccuracies, chance of leakage and or serious accidents could easily occur.

Before you begin, consult the manufacturer product specification and manual for any type of chemical dosing operation. If you are unsure, or do not know where to begin, then, we’re here to help. When you have any questions installing dosing pumps, we encourage you to contact WRS

Safety Always Comes First

- What type of chemicals will you be working with (their toxicity, corrosiveness and compatibility with what you are dosing)

- Environment: where will you setting up the dosing system. What else is nearby.

- Personal Protective Equipment for all operators (and others within the environment).

- Required PPE for operators and the surrounding environment.

- Consider storage protection.

- Make sure to thoroughly read manufacturer product specification and installation manual.

Setting Up Dosing Pumps

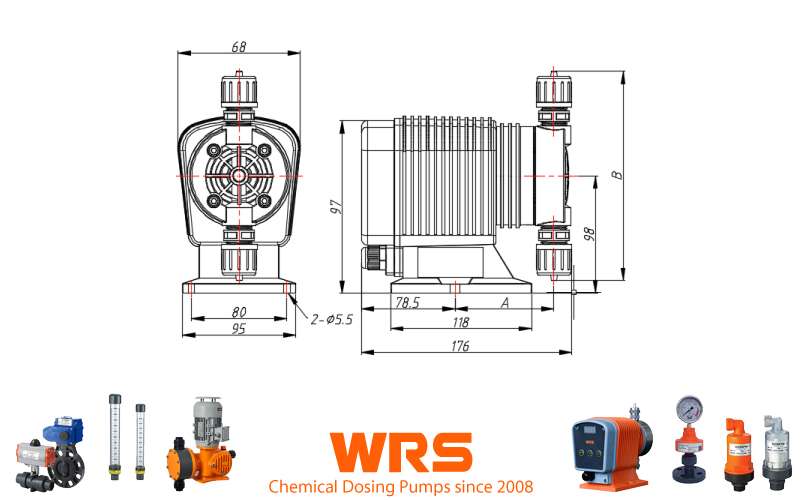

Below diagram shows the basics of dosing systems.

Since dosing pumps are meant to work on a high level of accuracy, the components need to be installed correctly for the best results. The dosing pumps and its components such as holding tanks need to be fully compatible with the chemical that is being metered; otherwise you may later find there are corrosion in the components or worst yet accidents.

Most dosing pumps will need specialised parts if high temperature, high pressure or highly corrosive materials need to be dosed. In the medical industry, for example, flexible plastic dosing pipes are used so that it is easier to replace them, or disinfect them for repeated use.

Before installation, a good spot for the pump and its parts should be mapped out, as there may be an accumulation of heat or corrosive chemicals which can damage surrounding areas and machinery. A common mistake people make is installing the dosing pump next to a water meter, because doing so can cause sludge to build up or rust to develop over short period of time.

The pump should ideally be installed next to compressed air and below the dosing point to prevent siphoning. This has the added advantage of protecting the pump from harsh weather elements as well as sunlight damage which can eventually crack the metering system outer layer.

Although dosing pumps are generally designed to withstand corrosion, it is better to place them inside a special cabinet or protective shed.

The holding tank or product container is another matter of particular importance. Bulk containers can be stored away from the site, if it is back up stock or will be unused for a long time. As long as bulk handling equipment is kept handy, the exact area of storage doesn’t matter. However, for chemicals that are needed for consistent and immediate use and have a short lifespan, it is imperative they are kept near the dosing pump to avoid over handling.

Talk to us for all your chemical dosing pump related questions and requirements, WRS has been manufacturing Chemical Dosing Pumps since 2008, with a factory size over 33,400sqm and supplying to over 50 countries around the world means that you’ll be getting expert advice and solutions that meet your particular requirements. Contact WRS Metering Pump Experts