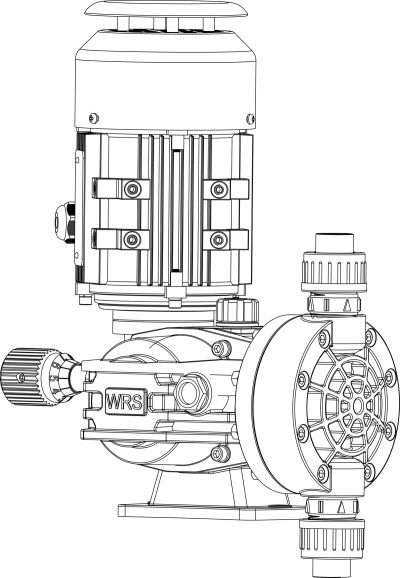

MOTOR DRIVEN DOSING PUMP

The MB series metering pump is a volumetric, mechanically operated reciprocating metering pump. It is widely used in industrial and scientific industry such as petrochemical, chemical processing, food, pharmaceutical, paper, light industry, agriculture, water plant environmental protection, etc., and it is responsible for the measurement and addition of various media in the process. Different pump head materials are available to handle different type of fluid. The standard configuration is PVC material, and materials such as 304, 316, PVDF are available too. MB series metering pumps can pump corrosive or non-corrosive liquid without solid particles at the temperature range of -15 ° C ~ 60 ° C and a viscosity range of 0.3 ~ 1000 cps. The rated flowrate of the pump ranges from 10 to 1800 l/h, and the corresponding maximum output pressure is 10 to 1 bar. The flowrate of the pump can be adjusted by adjusting the rotation of the handwheel, and the pump can be adjusted from 0% to 100% regardless of whether the pump is running or not. Steady-state accuracy is ±1% over the 30% to 100% flow range. It is a metering pump with simple structure, low energy consumption, accurate measurement and practicality. Different types of metering pumps can be equipped with explosion-proof motors or variable frequency motors as required.